Products

Now: Home>Products

YN Series Heat Recovery System from Waste Water

|

YN Series Heat Recovery System from Waste Water

|

||

|

||

| Standard structure | ||

| This system is composed of double-drum filter, vertical stainless steel centrifugal pump, high-efficiency principal heat exchanger, intelligent electric control system, water level controller, automatic backflush cleaning system, underground insulation pool and other auxiliary parts such as pipelines and pneumatic valves, etc. ● Double-drum filter As the filtration unit in the whole system, this device is mainly responsible for cleaning and filtering impurities. The device has automatic detection function, when one drum is jammed, an alarm signal will be issued to the user, and the other drum is automatic switched on. (for guarantee of normal operation of equipment, please clean the jammed drum in time). ● High-frequency principal heat exchanger It is made of superior and corrosion-proof stainless steel material with special technology and reasonable internal structure, the rate of heat exchange is over 80%, the coefficient of heat exchange is above 5000w/m, and the service life is superior to similar products. ● Intelligent electric control system Electric appliances are controlled by programmable logic controller (PLC), various parameters can be set in accordance with practical needs of users, and all Chinese HMI is adopted. This system has self-protection and alarm functions to guarantee operating stability of various components so as to extend system maintenance period to the greatest extent. ● Water level controller and automatic backflush cleaning system This water level controller can automatically adjust the opening degree of pump according to water level in pool, and the system can shut down automatically when water reaches the lowest level. With extension of service time, the efficiency of principal heat exchanger will reduce due to adhesion of sewages on heat exchange plate. Therefore, we install automatic cleaning system, automatic aerating device and automatic sewage-drain device inside the system to clean sewages inside the heat exchange plate. When the whole machine stops, the automatic backflush cleaning system can start automatically in accordance with operating time so as to achieve high efficiency of the whole system. ● Underground insulation pool (equipped by users) (1) One sewage storage pool with coarse filter system is equipped, and different factories should determine the size of sewage insulation pools according to their water discharge. (2) One fresh and hot water insulation and storage pool with constant pressure water pump system is equipped, which size should be determined by different factories according to their own conditions. (Note: this pool is not necessary for machines producing long yarns, which can be directly connected into machine table for use). Heat preservation and anti-cooling of system pipeline are made by means of mineral wool or aluminum silicate wool. |

||

| Main features | ||

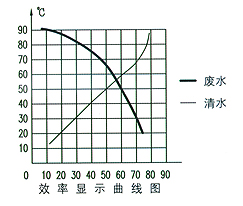

| ● Energy conservation High-efficiency principal heat exchanger can rise the temperature of equivalent cold and fresh water to be more than 80% of temperature of originally drained hot waste water so as to save a lot of fuel. ● High efficiency After exchange of cold and fresh water with hot sewage, the temperature of cold and fresh water has risen close to the required technological temperature, so technological requirements can be satisfied only by adding a small quantity of steam so as to shorten temperature rise time and running time of circulating pump, save consumption of steam and power and improve productivity. ● Environmental protection This system has perfect filtering function and can eliminate most impurities in waste water to avoid blocking of the drained waste water to passage. In the meantime the temperature of waste water after exchange between hot sewage and cold and fresh water has dropped close to constant temperature, so cooling treatment is no longer needed when waste water is drained to sewage treatment pond, hence decreasing usage amount of chemicals, saving costs for waste water treatment, obviously reducing generation of sludge, and meanwhile alleviating pollution to atmosphere due to less coal burning. |

||

|

Scan QR code to follow us

Scan QR code to follow us